|

NEW:

Brazed Plate Dimensions Brochure -

Hi Pressure Brazed Plate Condensers/Evaporaters -

WVO - Waste Vegetable Oil Brazed Plate Heaters

SEC Brazed Plate Heat Exchangers (BPHE) Get assistance 1.800.335.6650 The highly efficient brazed design and excellent value of SEC Brazed Plate heat exchangers (BPHE flat plate) makes them an economical choice for your heat transfer applications. Manufactured to the highest standards utilizing the latest brazing production technology our Copper, Nickel and Titanium brazed, Single and Double Wall and Air Gap Brazed Plate Heat Exchangers meet the demanding quality requirements of the internationally recognized industry standards organizations. |

|

SEC Brazed Plate heat exchangers are pressure rated for 435 psi at 437°F.

| |

|

Applications:

|

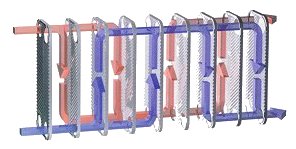

A specially designed corrugation pattern plate promotes highly turbulent flow characteristics. High turbulence dramatically improves the heat transfer rate and reduces the amount and the possibility of deposit build up. |

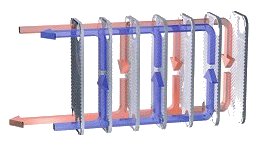

| SEC Brazed Plate Heat Exchanger Flow Channel Diagram | |

One-Pass means Channels are Parallel. |

Multi-Pass means a System of Channels is divided into groups which are connected in series. |

|

SEC Brazed Plate Heat Exchangers (BPHE Flat Plate) offer the following Advantages.. | |

|

|

|

|

SEC Brazed Plate heat exchangers consist of specially formed stainless steel plates, vacuum brazed together to form a highly efficient heat transfer device. The plate size, number of plates and connection types are varied to match the customers heat transfer requirements precisely. |

|

SEC Brazed Plate Heat Exchangers (BPHE Flat plate) Technical Information..

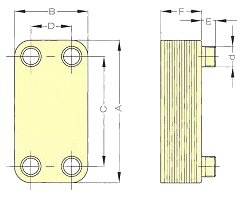

| Brazed Plate Models | Dimensions (inches) | Plate Area | Channel Volume | Maximum Flow | Maximum Number of | Weight (empty) | ||||

| A | B | C | D | F | (Sq.ft) | (USGAL) | (GPM) | Plates(NP) | (Lbs) | |

| M-14A | 7.6 | 3.1 | 6.1 | 1.6 | .39+.09np | 0.13 | 25 | 60 | ||

| M-312 | 12.1 | 3.1 | 10.9 | 1.6 | .39+.09np | 0.23 | 0.012 | 20 | 60 | 1.7+0.1np |

| M-25 | 20.0 | 5.0 | 17.5 | 2.5 | .49+.09np | 0.62 | 0.020 | 75 | 120 | 5.0+.44np |

| M-31B | 12.0 | 5.0 | 9.8 | 2.8 | .36+.09np | 0.35 | 0.012 | 55 | 120 | 3.1+0.3np |

| M-110X/X2J | 20.9 | 9.8 | 18.0 | 6.9 | .51+.09np | 1.22 | 0.043 | 120 | 150 | 11.2+0.9np |

| M-110H | 18.2 | 10.0 | 14.9 | 6.7 | .53+.11np | 1.16 | 185 | 200 | ||

| M-110Y | 20.6 | 9.5 | 16.9 | 5.8 | .53+.11np | 0.89 | 185 | 200 | ||

| M-110Z | 20.6 | 9.5 | 16.9 | 5.8 | .53+.11np | 1.11 | 250 | 200 | ||

Technical Parameters Diagram for Brazed Plate Heat Exchangers (for use with above chart) |

Standard Connection Types for Brazed Plate Heat Exchangers: Solder (sweat) - Threaded (NPT) - Flanged |

|

Design Parameters: *(economic versions) |

|

Brazed Plate Model |

Solder (sweat) | Threaded (NPT) | Flanges | |||

| d* (in) | E (in) | d (in) | E (in) | d (in) | E (in) | |

| M-14A | 3/4” | 3/4” | 3/4” NPT (male) | 7/8” |

Flanged Connections are available for the M-110(s) (custom order) | |

| M-312 | 3/4" | 3/4” | 3/4” NPT (male) | 7/8” | ||

| M-25 | 1 - 3/8” | 13/16” | 1 - 1 1/4” NPT | .80” | ||

| M-31 | 1” | 1-3/8” | 1” NPT (male) | 1-1/8” | ||

| M-110 | 2” | 1-1/4” | 1.5, 2.5 or 3" NPT | 1-1/4” | ||

Titanium or Stainless Steel hot tub, spa, swimming pool heat exchangers are easy to open, easy to clean, easy to install and service..

|